Diamond formation

Natural

- The Earth’s core is the largest carbon storage on Earth — roughly 90% is buried there.

- Scientists have shown that the oceanic crust that sits on top of tectonic plates and falls into the interior contains hydrous minerals and can sometimes descend all the way to the core-mantle boundary.

- The temperature at the core-mantle boundary is at least twice as hot as lava, and high enough that water can be released from the hydrous minerals. Therefore, a chemical reaction similar to rusting steel could occur at Earth’s core-mantle boundary.

- Researchers from the Arizona State University conducted experiments where they compressed iron-carbon alloy and water together to the pressure and temperature expected at the Earth’s core-mantle boundary, melting the iron-carbon alloy.

- The researchers found that water and metal react and make iron oxides and iron hydroxides, just like what happens with rusting at Earth’s surface. However, they found that for the conditions of the core-mantle boundary carbon comes out of the liquid iron-metal alloy and forms diamond

- They found that carbon leaking from the core into the mantle by this diamond formation process may supply enough carbon to explain the elevated carbon amounts in the mantle.

- They also predicted that diamond rich structures can exist at the core-mantle boundary and that seismic studies might detect the structures because seismic waves should travel unusually fast for the structures.

Lab Grown

- Lab-grown diamonds are diamonds that are produced using specific technology which mimics the geological processes that grow natural diamonds.

- They are not the same as “diamond simulants” – LGDs are chemically, physically and optically diamond and thus are difficult to identify as “lab-grown.”

- While materials such as Moissanite, Cubic Zirconia (CZ), White Sapphire, YAG, etc. are “diamond simulants” that simply attempt to “look” like a diamond, they lack the sparkle and durability of a diamond and are thus easily identifiable.

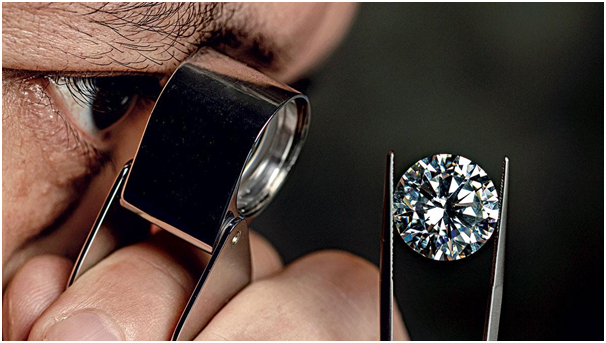

- However, differentiating between an LGD and an Earth Mined Diamond is hard, with advanced equipment required for the purpose.

- There are multiple ways in which LGDs can be produced. The most common (and cheapest) is the “High pressure, high temperature” (HPHT) method. this method requires extremely heavy presses that can produce up to 730,000 psi of pressure under extremely high temperatures (at least 1500 celsius).

- Usually graphite is used as the “diamond seed” and when subjected to these extreme conditions, the relatively inexpensive form of carbon turns into one of the most expensive carbon forms.

- Other processes include “Chemical Vapor Deposition” (CVD) and explosive formation that creates what are known as “detonation nanodiamonds”.

What are LGDs used for?

- LGDs have basic properties similar to natural diamonds, including their optical dispersion, which provide them the signature diamond sheen.

- However, since they are created in controlled environments, many of their properties can be enhanced for various purposes.

- For instance, LGDs are most often used for industrial purposes, in machines and tools.

- Their hardness and extra strength make them ideal for use as cutters. Furthermore, pure synthetic diamonds have high thermal conductivity, but negligible electrical conductivity. This combination is invaluable for electronics where such diamonds can be used as a heat spreader for high-power laser diodes, laser arrays and high-power transistors.

- Lastly, as the Earth’s reserves of natural diamonds are depleted, LGDs are slowly replacing the prized gemstone in the jewelry industry. Crucially, like natural diamonds, LGDs undergo similar processes of polishing and cutting that are required to provide diamonds their characteristic lustre.

| Practice Question

1. What are the steps taken by the government in the promotion of Lab grown Diamonds? |