Understanding waste-to-energy plants

Context: The Kerala government recently announced the State’s first waste-to-energy project in Kozhikode. The planned facility is expected to be built in two years and generate about 6 MW of power. There are around 100 waste-to-energy projects around the country but only a handful of them are operational.

What do waste-to-energy projects do?

- Waste-to-energy projects use non-recyclable dry waste to generate electricity. The process increases the State’s power generation capacity and eases the solid waste management (SWM) burden.

- Commonly, solid waste in India is 55-60% biodegradable organic waste, which can be converted into organic compost or biogas; 25-30% non-biodegradable dry waste; and around 15% silt, stones, and drain waste.

- Of the non-biodegradable dry waste, only 2-3% — including hard plastics, metals, and e-waste — is recyclable.

- The remainder consists of low-grade plastic, rags, and cloth that can’t be recycled.

- This fraction of the non-recyclable dry waste is the most challenging portion of the present SWM system; the presence of these materials also reduces the efficiency of recycling other dry and wet waste.

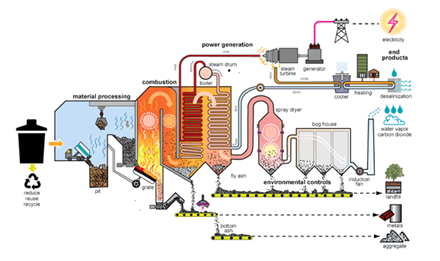

- It is this portion that waste-to-energy plants use to generate power. The waste is combusted to generate heat, which is converted into electricity.

Why do waste-to-energy plants fail?

While waste-to-energy plants seem like a simple solution, they have several challenges en route to becoming feasible.

- First is the low calorific value of solid waste in India due to improper segregation.

- The calorific value of mixed Indian waste is about 1,500 kcal/kg, which is not suitable for power generation. (Coal’s calorific value is around 8,000 kcal/kg.)

- Biodegradable waste has high moisture content and cannot be used for power generation.

- The calorific value of segregated and dried non-recyclable dry waste is much higher, at 2,800-3,000 kcal/kg, sufficient to generate power.

- Nonetheless, segregation should be streamlined to ensure the waste coming to the facility has this calorific value.

- Second is the high costs of energy production.

- The cost of generating power from waste is around ₹7-8/unit, while the cost at which the States’ electricity boards buy power from coal, hydroelectric, and solar power plants is around ₹3-4/unit.

- While State electricity boards are considering purchasing power from newer renewable energy sources like waste-to-energy, the price of the power generated needs to halve.

- Finally, many waste-to-energy projects have failed because of improper assessments, high expectations, improper characterisation studies, and other on-ground conditions.

How can the plant tackle challenges?

- Operating waste-to-energy projects also depends on parameters like

- The municipal collection efficiency

- Waste segregation

- Moisture content

- The operational efficiency of existing biodegradable-waste-processing plants.

- If these plants have operational woes, the nature of waste will change drastically to have high moisture content and low calorific value, which will compromise power generation.

- Setting up waste-to-energy projects is complex and needs the full support of the municipality, the State and the people.

- To overcome its various challenges, the municipality must ensure that only non-biodegradable dry waste is sent to the plant and separately manage the other kinds of waste.

- Importantly, the municipality or the department responsible for SWM should be practical about the high cost of power generation, and include the State electricity department, perhaps as a tripartite agreement between the municipality, the plant operator, and the power distribution agency. It is also crucial to conduct field studies and learn from the experience of other projects.

| Practice Question

1. What are waste to energy plants? Elaborate on the issues faced by such plants? |