Sustainability Science for FMCGs

Relevance: GS – 3 : Science and Technology – developments

Why in the news?

- India has launched a new public-private partnership (PPP) initiative, the Anusandhan National Research Foundation (ANRF), aimed at strengthening research and development through academia-industry collaborations.

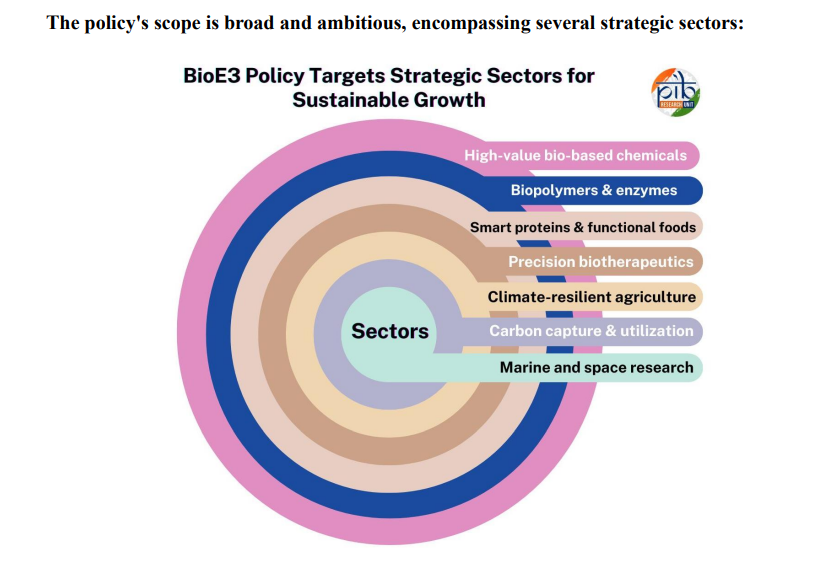

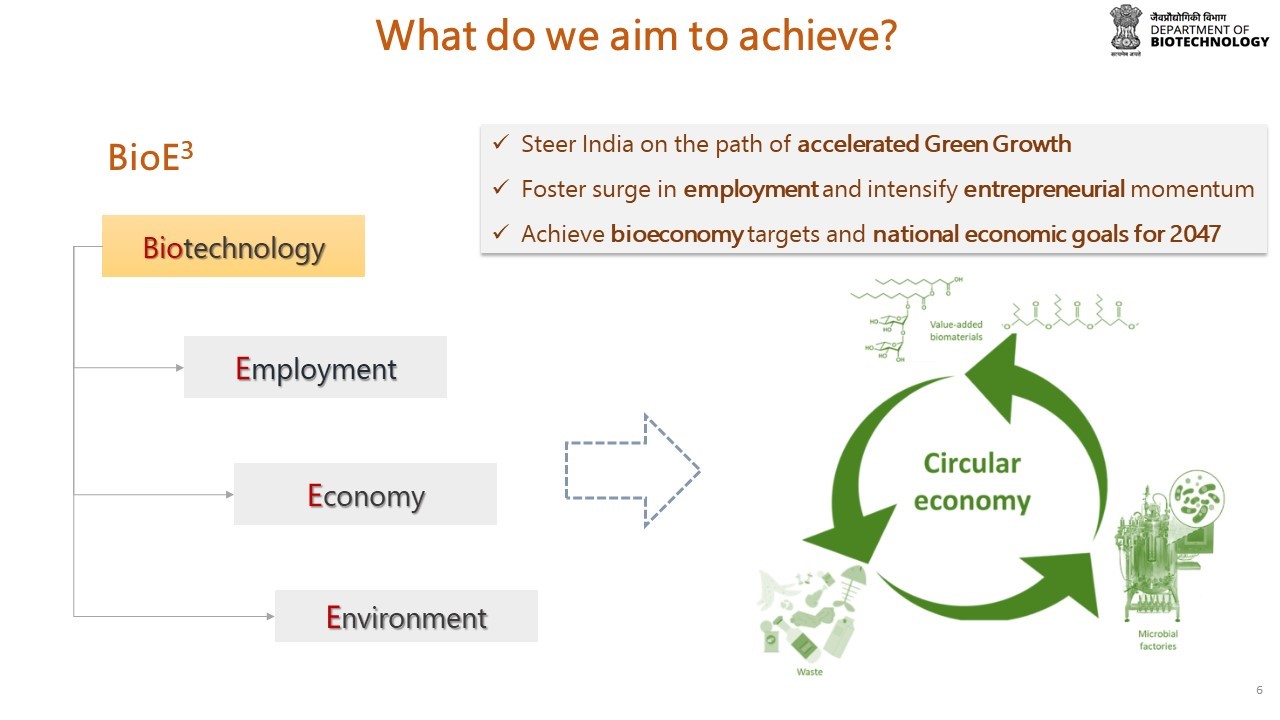

- The government recently announced the BioE3 policy (Biotechnology for Economy, Environment, and Employment), which:

- Highlights the role of bioeconomy in supporting economic growth, sustainability, and climate commitments.

- Encourages the shift of chemical-based industries toward bio-based, sustainable models.

- This policy shift opens up avenues for the FMCG sector to explore sustainable practices and align with bio-based innovations, as well as for research to assess new technologies’ effects on traditional FMCG practices.

Reducing Palm Oil in Soap Production

- Environmental Impact of Soap Industry: Soap manufacturing contributes significantly to greenhouse gas emissions and biodiversity loss.

- Heavy reliance on palm oil has led to deforestation, with about 90% of palm plantations located in Borneo, Sumatra, and the Malay Peninsula.

- Replacing Palm Oil: Palm oil offers higher yield compared to other vegetable oils, making it more cost-effective for farmers and affordable for consumers.

- It constitutes around 40% of global vegetable oil demand, making its reduction challenging for industry practices.

Technological Innovations to Reduce Palm Oil in Soaps

- Potential of New Technologies: Emerging synthetic biotechnologies offer potential solutions to replace or reduce palm oil usage in soap production.

- Role of Palm Oil in Soap: Palm oil provides essential fatty acids for two main functions in soap:

- Surfactant/Cleansing Function: 15-20% of the lower chain fatty acids in palm oil aid in cleansing.

- Structural Function: Most of the longer chain fatty acids serve to provide structure to the soap bar.

- Synthetic Alternatives: Synthetic biotechnologies could develop artificial fatty acid chains, particularly those that mimic the structural properties of palm oil.

- Plant-Based Alternatives: Local plant or bio-based materials, such as plant-based polysaccharides, could replace the non-essential “structuring” portion of the Total Fatty Matter (TFM) in soaps.

- Added Functional Benefits: Reducing the “hard soap” component can create room for beneficial agents, such as:

- Antimicrobial Peptides: Enhances the germ-protection function of the soap.

- Biologically Active Molecules: Boosts the skin’s immunity while providing germ protection.

Need for Government and Civil Society Support

- Collaborative Effort Required: Strong backing from both government and civil society is essential to develop sustainable alternatives in soap production.

- Bio-Based or Bio-Synthetic Materials: Developing alternatives that replicate the structural integrity of traditional soap bars.

- Sustainable Packaging: Innovations to reduce or eliminate plastic use in soap packaging.

- Role of ANRF and BioE3 Policy: The recent Anusandhan National Research Foundation (ANRF) initiative, aligned with the BioE3 policy, can: Fund research and development partnerships; Recognize the importance of reinventing legacy products alongside the introduction of new sustainable options.

Pathway to Sustainable Palm Oil and Soap Production

- Reliance on Sustainable Palm Oil: Until bio-synthetic and bio-engineered alternatives are fully viable, soaps and other daily-use products will continue to depend on sustainable palm oil from domestic and international sources.

- India’s National Mission on Edible Oils-Oil Palm (launched August 2021) aims to expand oil palm cultivation to 1 million hectares and increase crude palm oil production to 1.12 million tonnes by 2025-26.

- Environmental Considerations: Sustainable plantations must adhere to “No Deforestation, No Peat” principles, and site selection should prioritize biodiversity conservation.

- A need exists for ecological research to understand the long-term impacts of monocultures on India’s biodiversity and to promote regenerative agriculture practices with smallholder farmers.

- Economic Implications:

- Costs of sourcing locally grown sustainable palm oil and investing in innovation to reduce imports may affect product pricing, impacting market share in competitive segments.

- Government incentives, research funding, and fiscal support can mitigate these costs, promoting sustainable practices and driving innovation.

Regulatory Support for Reducing Palm Oil Use:

- Current Soap Standards: Presently, soap grades in India are defined by fatty material content, reinforcing a misconception that higher fatty content equates to superior quality.

- Proposed Shift to Performance-Based Standards: Updated regulations should transition to horizontal, performance-based criteria, aligning with standards in developed markets that prioritize consumer benefits, safety, and sustainability.

- Sustainability Labelling: Mandatory labels indicating sustainability scores based on procurement and production practices can empower consumers to make informed choices.

- ANRF and BioE3 Policy’s Role: The Anusandhan National Research Foundation (ANRF) and the BioE3 policy provide a foundation for advancing a bio-based economy through academia-industry partnerships.

- Everyday products, like soaps, offer an impactful starting point, enabling India to progress toward sustainable and self-reliant production practices.

Associated article

https://universalinstitutions.com/india-malaysia/

Source: https://www.thehindu.com/opinion/op-ed/sustainability-science-for-fmcgs/article68804339.ece

Mains question

Discuss the role of sustainable palm oil production in India’s FMCG sector and examine the regulatory, economic, and technological challenges associated with reducing palm oil dependency in soap manufacturing. (250 words)