SLUGGISH KAVACH DEPLOYMENT

Syllabus:

GS 2: Infrastructure: Energy, Ports, Roads, Airports, Railways etc.

GS 3 : Disaster and Disaster Management.

Focus:

The railway accident involving the Kanchenjunga Express in West Bengal has spotlighted the slow deployment of Kavach, India’s Automatic Train Protection system. Despite adequate funding, the sluggish installation pace raises concerns about safety and the Railways’ ability to prevent future accidents.

Source: UGI

The Railway Accident and Urgent Need

- Incident aftermath: The railway accident involving the Kanchenjunga Express in West Bengal highlighted the absence of Kavach, India’s Automatic Train Protection (ATP) system, resulting in ten fatalities.

- Annual toll: On average, 80 fatalities occur annually in train collisions across India.

- Government response: Railway Minister Ashwini Vaishnaw reviewed progress on Kavach 4.0 a week after the incident, directing a “mission mode” installation approach.

- Funding availability: Data indicate that funding availability is not the bottleneck for Kavach implementation; the challenge lies in the deployment pace.

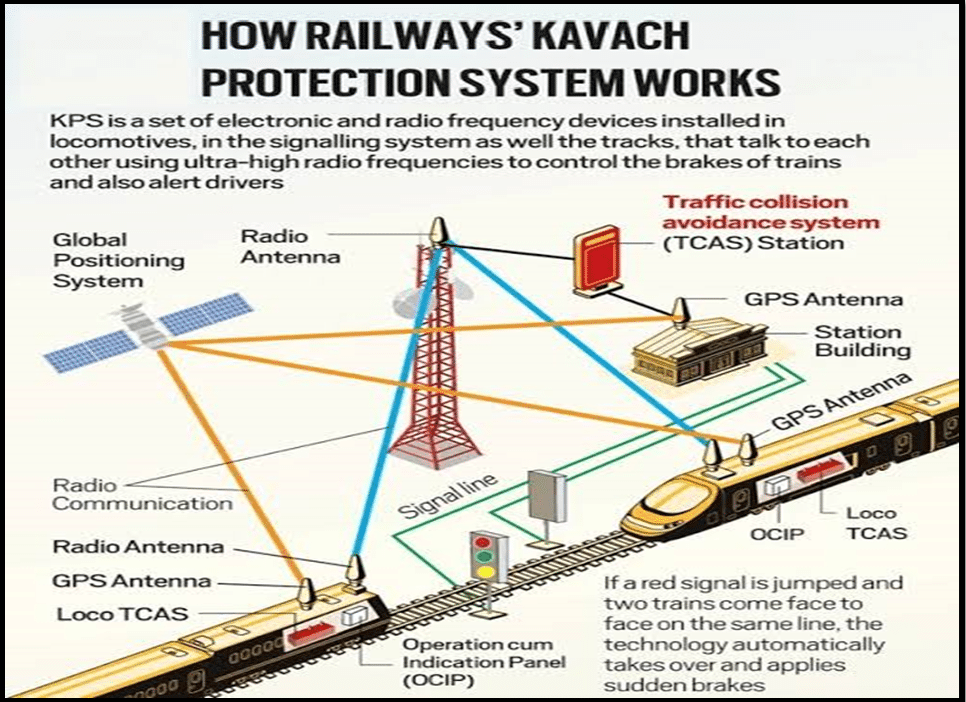

- Functionality of Kavach: Kavach alerts loco pilots of signal overshoot risks and automatically applies brakes if necessary, relying on RFID tags, engine equipment, and radio towers.

Financial Feasibility and Budget Allocation

- Track installation cost: Installing Kavach costs ₹50 lakh per kilometre, including station equipment, totaling about ₹34,000 crore for the Indian Railways’ 68,000 km network.

- Engine equipment cost: Each engine’s equipment installation costs ₹70 lakh, summing up to ₹10,640 crore for the Railways’ 15,200 engines.

- Total deployment cost: Overall, implementing Kavach across tracks and engines amounts to approximately ₹45,000 crore.

- Budget comparison: Even with a substantial increase in Railways’ capital expenditure to ₹2,52,000 crore in FY25, the annual deployment cost of ₹4,500 crore for Kavach remains less than 2% of this budget.

- Financial perspective: The figures demonstrate that Kavach deployment across the entire network requires a small fraction of the Railways’ annual budget.

Current Progress and Challenges

- Installation pace: The current installation rate of Kavach is sluggish, with initial passenger train trials starting in February 2016 and national adoption in July 2020.

- Coverage statistics: As of February, only 1,465 Rkm (approximately 2% of total route length) and 139 engines (less than 1% of total) are equipped with Kavach.

- Deployment projection: At the current pace, it would take 46 years to cover all route kilometres and over a hundred years to equip all engines with Kavach.

- Acceleration needed: To achieve a 10-year deployment target, the installation pace must increase to 6,800 Rkm per year for tracks and 1,500 engines per year.

- Implementation challenges: Challenges include skilled labor requirements, specialized equipment needs, and traffic management during installation.

Primary Reasons Behind Railway Accidents

- Infrastructure Defects: Defective infrastructure, including tracks, bridges, and rolling stock, often results from poor maintenance, aging, vandalism, sabotage, or natural disasters.

- Outdated Infrastructure: Much of the railway infrastructure dates back to the 19th and 20th centuries and has not been upgraded to meet modern standards and growing demand.

- Funding Issues: The railway system suffers from a lack of funds, corruption, and inefficiency, hindering development and maintenance efforts.

- Overcapacity: Many routes operate at over 100% capacity, increasing the risk of accidents due to congestion and overloading.

- Human Errors: Railway staff errors, caused by fatigue, negligence, corruption, or disregard for safety protocols, can lead to wrong signaling, miscommunication, overspeeding, and overlooking hazards.

Efforts to Reduce Accidents

- Rashtriya Rail Sanraksha Kosh (RRSK): Established in 2017-18 with a corpus of ₹1 lakh crore over five years for critical safety-related works such as track renewals and signaling projects.

- Technological Upgradation: Introduction of improved coach and wagon designs, including Modified Centre Buffer Couplers, BMBS, and Automatic Fire & Smoke Detection systems. Kavach, an Automatic Train Protection system, has also been developed.

- LHB Design Coaches: Lighter and safer coaches based on German technology with better anti-climbing features, fire retardant materials, higher speed potential, and longer service life.

- GPS-based Fog Pass Device: A handheld GPS-enabled device helps loco pilots navigate in foggy conditions by displaying the exact distance to approaching landmarks and alerting with a loud buzzer.

- Modern Track Structure: Utilization of stronger and more durable materials like Prestressed Concrete Sleepers, higher Ultimate Tensile Strength rails, and Steel Channel Sleepers on girder bridges.

| What is Kavach?

About:

Components:

|

Way Forward

- Accelerate Deployment: Increase the installation pace to 6,800 Rkm per year for tracks and 1,500 engines per year to achieve a 10-year deployment target.

- Mission Mode Implementation: Adopt a mission mode approach, as directed by the Railway Minister, to ensure focused and expedited progress.

- Streamline Processes: Simplify and standardize the procedures for deploying Kavach to reduce bureaucratic delays and enhance efficiency.

- Leverage Skilled Labor: Invest in training and employing skilled labor to meet the specialized requirements of Kavach installation.

- Enhance Coordination: Improve coordination between various stakeholders, including equipment suppliers, railway officials, and government agencies, to ensure smooth implementation.

- Regular Monitoring: Establish a robust monitoring and evaluation framework to track progress, address bottlenecks, and ensure adherence to the deployment timeline.

Conclusion

The slow deployment of the Kavach system, despite financial feasibility, underscores the need for focused efforts and streamlined processes. Accelerating the installation pace and enhancing coordination among stakeholders are crucial to ensuring safety and preventing train collisions in India.

Source:The Hindu

Mains Practice Question:

Discuss the strategic implications of India’s evolving role in balancing European and Asian geopolitics. How can India leverage its historical ties and current alliances to strengthen its position in the global arena?

Associated Article:

https://universalinstitutions.com/railway-safety-and-accountability-in-india/